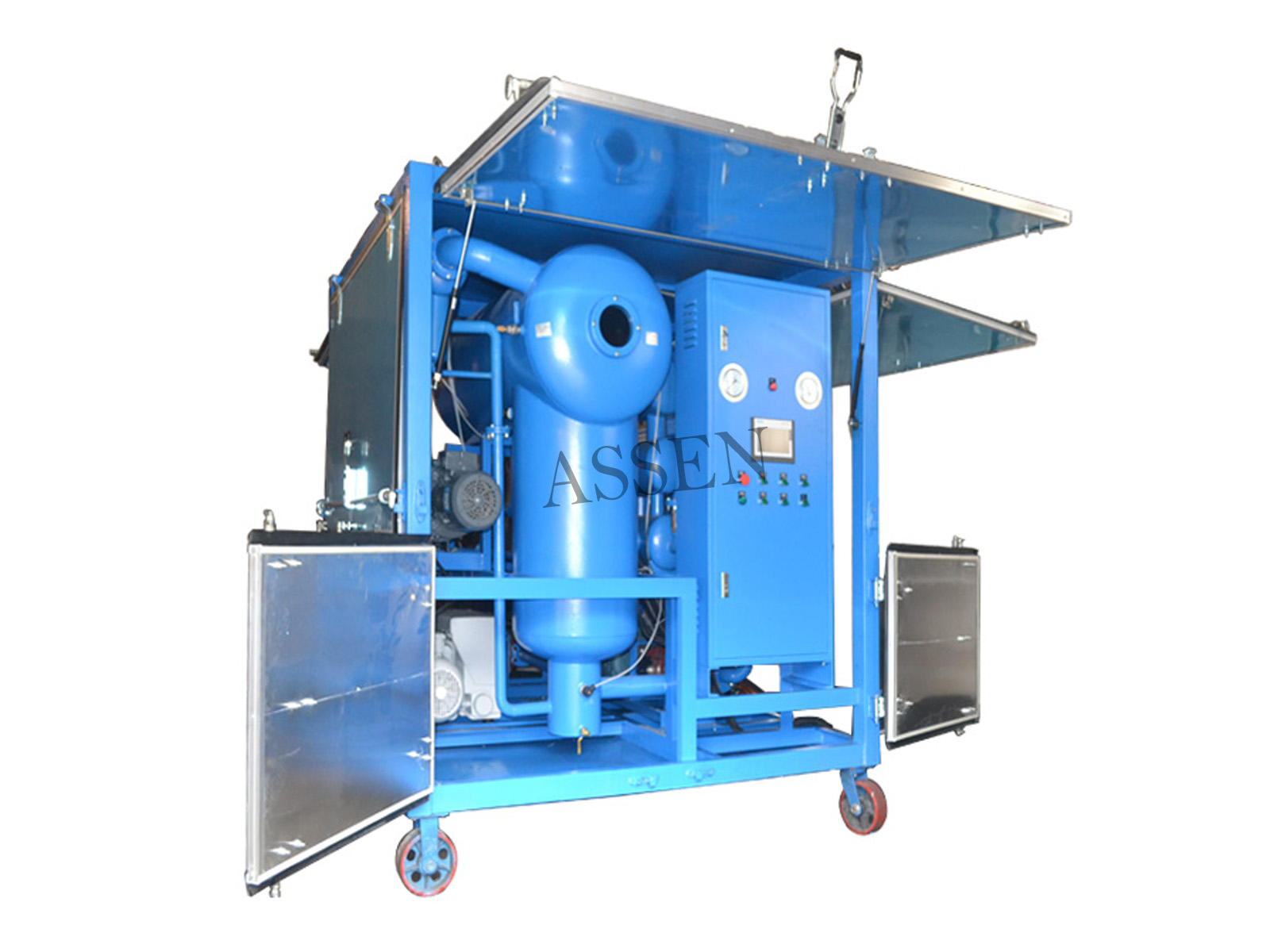

Description

Application

Oils inside transformers are mainly for insulating purpose- apart from which they also suppress corona and arcing, and also act as coolants inside the machines. These oils must be maintained absolutely clean and dry in order to achieve and sustain the optimal insulating performance and dielectric strength. Here rises the need for transformer oil purification process. ASSEN ZYD Metallic Canopy covered Insulating Oil Purifier Plant is the key to transformer reliability, performance and longevity. Your transformer’s insulating oil should be free from moisture, dissolved gases and particles that accumulate as the oil ages. Even some new oils may require treatment to limit these contents to acceptable levels.

Performance:

In a single pass through the purifier at a full flow rate:

Water Removal:

From 50 ppm down to less than 5 ppm in a single pass & down to 3 ppm after two passes. (According to the PPM Tester)

Gas Removal:

From fully saturated with air (10% to 12% by volume) down to less than 0.1% by volume.

Particulate Matter Removal:

98% of particles over 0.5mm or over 1 mm or over 5mm at customers preference.

Dielectric Strength:

Improve dielectric strength up to 75-80KV for New oil.

Acid Removal:

after treatment, the acid value will down to less than 0.1mgKOH/g

Free Carbon Removal:

there is no free carbon’s residue

Features

1.Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤ 5Pa

2.Two vacuum separating chambers, efficient oil film sprayer, increasing separating size and separating time to ensure the dry-level and dielectric strength improving greatly.

3.Double-horizontal film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas from oil.

4.Multi-stage precision filtration system, mesh filtration combined with molecular adsorption technologies.

5.Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

6.Double-infrared liquid level sensor, pressure protective system to ensure machine operation easy and safely.

7.Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

8.Functions of live line work onsite, vacuum drying and vacuum oiling.

Technical Data

| Parameters | Unit | ZYD-30 | ZYD-50 | ZYD-100 | ZYD-150 | ZYD-200 | ZYD-250 | ZYD-300 | |

| Flow | L/min | 30 | 50 | 100 | 150 | 200 | 250 | 300 | |

| Working vacuum | MPa | 0.08 ~ 0.099 | |||||||

| Working Pressure | MPa | ≤0.3 | |||||||

| Temperature Range | ℃ | 20 ~ 80 | |||||||

| Power | Three Phase 50HZ380V(as per the customer’s requirements) | ||||||||

| Working Noise | dB(A) | 75 | 75 | 75 | 80 | 80 | 80 | 80 | |

| Heating Power | kW | 30 | 30 | 45 | 60 | 75 | 90 | 120 | |

| Total Power | kW | 35.5 | 37.5 | 52.5 | 71.4 | 86.5 | 102.5 | 135 | |

| Inlet/Outlet | mm | φ25 | φ32 | φ42 | φ50 | φ50 | φ60 | φ60 | |

| Weight | kg | 600 | 800 | 1050 | 1400 | 1800 | 2000 | 2200 | |

| Overall | Length | mm | 1050 | 1100 | 1200 | 1450 | 1600 | 1800 | 1900 |

| Width | mm | 750 | 800 | 950 | 950 | 1100 | 1200 | 1200 | |

| Height | mm | 1350 | 1400 | 1500 | 1650 | 1800 | 1900 | 1900 | |

Advantages

Comparing with the single-stage vacuum oil purifier, this machine dewaters, degases and removes the impurities more quickly, more completely, and improves the oil breakdown voltage much higher. As the bridge-type vacuum linking system, it is used for filtrating system as well as an independent vacuum power supply to vacuum oiling of power equipment.